By JD at Cherokee West

As a child my first concept of prepping was a basement in a large log cabin sort of house in which lived some friends of our family. The stairs in the house were wooden and unfinished, the type you might see on an outdoor deck or patio. I could see beneath them as I walked up to the second story to play. Bathed in the glow of a single, naked dangling light bulb (like the ones you see flickering and swaying in horror movies) sat a giant Saint Bernard dog. I have long forgotten the name of the dog but can clearly visualize an image of his shadow cast onto that door. Years later I would find that behind that door there was a room that housed a myriad of cans, bottles, bags, jugs, crates, barrels and all other manner of storage vessels full of all sorts of different foods, household items and just about everything else you could imagine. When asked what the contents of this room were for the owner’s response was simple: “We are prepared for anything.”

Now I’ve got a family of my own and I work in the shipping container industry. My duties are mostly technical but I’m also responsible for most of our company’s online endeavors, which involves quite a bit of reading and research. In my hours spent digging through articles and blog posts there are a few things that come up quite regularly. One of them is the idea of burying a shipping container to use as a shelter or storage space. I’ve heard a lot of stories about things like this, some in articles posted on the Internet, some in forum discussions, and a few tales even passed around the office. Using my what I’ve learned from my research, the knowledge of the 25+ years of combined industry experience I’m lucky enough to have here in my office, I’ve put together a few things that I think are important to know/do if you’re planning on buying a container and putting it in the ground.

To bury or not to bury… is that the question?

Should you bury shipping containers for use as storage or living space? This argument has been around for quite a while and I would like to make it clear that I am neither for, nor against the idea. I am not writing this article to try to get you to bury or not bury your container. I am going to assume that you’ve done your research and decided that this is the best option for you. If you haven’t, there are plenty of resources out there. There are forums with 25 page discussions that escalate to borderline html/text warfare. There are websites full of videos of men with an accent that makes them somehow sound less pretentious, and there are articles, books, videos, etc… The decline in the economy combined with the increased availability of information over the Internet has brought about an entire culture of do-it-yourselfers intent on navigating their own way through sometimes perilous paths for a multitude of their own reasons. Don’t get me wrong, I will always attempt something on my own before I ask for help but in the event that I get to a point where I feel that I no longer understand what I’m doing, or am uncertain about any decision I have made – I seek advice from someone who knows more than I do and depending on the severity of the situation – a qualified expert.

So let’s approach this question a different way. I am from a school of thought that assumes that anything that conforms to common sense and the laws of physics can be achieved or manifested in some form. So if I wanted to bury a cargo container to use as bunker, I wouldn’t be asking IF, I would be asking HOW. Because let’s face it, it’s been done (you’ll see this video on almost every single site that has a reference to burying a container.) Let’s assume that you’ve made up your mind: You’re going to bury the box. Here is the question: Are you able/qualified to bury a shipping container for use as storage or living space? I will be the first to admit that I am not. I am not confident, nor am I comfortable enough with my understanding of underground construction or the way that the forces of the world work to invest time, money, my life or the lives of my family in burying a shipping container for use as storage or living space. I could market the project once it was finished. I could even build you a mediocre, fairly entry level, WordPress blog/webpage about it. Or write you a 7 minute jam track song with a basic drum beat, 3 guitar solos, and some crazy programmed percussion about it. I mention that because those are things that I have studied or spent time doing. I don’t consider myself an expert in any of those fields but at one point or another I have fixed a 404 error, or played a Phrygian scale over a C# chord and then cashed checks as a result of it. My point here: Do the research, make informed decisions, and ask for help when you need it.

Your Project

The next thing to consider is your project.

I obviously can’t account for all of the variables in a project like this. I won’t be talking about the depth you should bury or how to reinforce your ISO container (which I think is must,) or the type of materials you should use when building. Like I said – I don’t know anything about underground construction and don’t intend to give bad advice so I’m not going to write about any of that. I will write about a few of the factors in the decision to use a shipping or cargo container as an underground bunker. Cost and convenience are two of the biggest. Cargo containers may be abundant in your area or you may already have one lying around, or some other reason may make a shipping container an obvious choice for you. You may have some experience working with them or be caught in the trend, but for whatever reason: you’re looking for advice on how to bury a shipping container underground for use as a bunker or storage.

Anatomy of a shipping container

Most shipping containers are made from Corten steel. Corten steel (also called “weathering steel”) is a strong steel alloy that is extremely rust resistant, if the paint on a container (also rust resistant) is damaged the exposed area will develop a thick oxide film that prevents it from rusting any further. Combined with the correct paint this makes them stand the test of time against the harsh conditions experienced during travel at sea. The doors seal making them wind and water tight and allowing them to effectively protect their cargo. A 20’ container on its own weighs around 5,000 lbs and is designed to hold up to 60,000 lbs worth of cargo while stacked up to 9 high. This seems like a tough, perfectly sound structure that could easily hold up a couple feet of dirt, right? If it were only that simple. The strength of these containers comes from the frame. Corrugated sides are helpful and corten steel is strong, but the sides of a container are only a few millimeter thick. They are slightly recessed so when the containers are loaded onto a truck, train, or stacked, the frame is the only part that actually makes contact with anything around it. The best analogy I have heard for this is a soda can. A soda can will support the weight of a grown man standing on it, or the weight of many cans stacked on top. But it only takes a very slight amount of pressure to the side of the can to cause it to flatten under his weight, or topple the stack. Also, if the can is dented or damaged before you start the experiment it will also yield the same result. The shapes of these two objects are different but the physics are relatively similar. Outside of the frame which is a very small part of the surface of the container, these boxes just aren’t designed to withstand constant force from all directions. This is why it is important to choose your container with care, a solid container is the difference between success… and just digging a hole and filling it up with money.

Quality/Condition of the container

Just as with most other products or services — you get what you pay for. There are always exceptions but as a general rule, if you want quality… you pay for it.

Cargo containers ride back and forth between continents on big ships in mostly open, salty air and though they have been coated with a special rust resistant paint no amount of metal, or colored goop accounts for damage that may occur during their travels, or just plain age. The tiniest hole from the smallest ding or rust spot could end up being your worst enemy if you plan to use your container as a storage or living space. I’ve seen gallons of water leak through a pinhole in the ceiling of a container over just a few days time.

New/1-Trippers

If price isn’t an issue, get a new one. You can often choose your color or even apply some sort of logo. However if you’re planning to put something underground, color probably isn’t an issue. There are also what are called 1-trippers. These are almost new containers that have been loaded at their point of origin and brought into a port and then unloaded. So in essence, someone else is paying for the trip over. I tend to think of it like buying a new car. The dealer drives the car before you buy it, salesmen take it on test drives and move it around the lot.. etc.. In this case just imagine that he drove it to the store and used it to bring home his groceries. 1-trippers are common in the containerized housing community and are relatively easy to acquire. They are rarely damaged and are almost always in near perfect condition.

Used/Wind and Water Tight/As-is

If you’re on a tighter budget there are used containers. Different companies tend to refer to different conditions in different ways. I work for a company that doesn’t deal in junk, so most of what we see in the used category is referred to as “Wind and Water Tight.” This means that the doors close to form a seal and the floor and walls all remain in good shape. If you were to stand inside one of these containers and have someone close the door (which is a great way to check out a container by the way) you would see absolutely nothing. No light, no moving air, just black. Wind and Water Tight might mean a few years old, a little rust and a few bumps and dings but nothing that would affect the structural integrity or its ability to protect cargo the way it was designed to do. They can be inspected professionally and certified as worthy but often this is just an added expense (usually passed onto the buyer by the dealer) so most people opt to inspect it themselves. Beyond that there are As-is containers, what you see is what you get. You may have some rust to sand, or a hole to patch, but if you’ve got the skills and the time it’s another way to save some money. Keep in mind that damage in the right area can affect the structural integrity of the unit, and its ability to stand up to the elements, so it’s always a good idea (especially when burying a container) to consult and engineer, architect, or just someone who knows about these sort of things to make sure that the unit is able to withstand whatever torture you have planned for it.

Reinforcements!

One of the most important parts of this process, second only to the container itself. As previously discussed shipping containers are not designed to withstand constant pressure on the side/top panels. Burying a shipping container successfully involves properly engineering your structure to withstand the amount of pressure exerted by however much dirt you plan to have around it. It may just be a few inches, or it may be a few feet. No matter what your plans the sides and roof of the container should be properly reinforced in the manner of your choosing to prevent accident or injury. You may choose wood framing, or bricks, or even cement but you must choose something. If you’re not sure hire an engineer or architect. It will be worth the extra bucks when your shelter is still there after the ground shifts from an earthquake or the next big rain. If you’re building a structure to keep you or your stuff safe, why take any chances?

Paint/sealant

This is another thing that might be easy to overlook but could end up being crucial to your project. Though corten steel is rust resistant neither the paint that is on the cargo container nor the metal are designed to withstand the effects of standing water or whatever other potentially corrosive factors hide in your soil. What things should you consider when looking into paint/sealant? Quality, durability, and chemical composition, I will not comment on the type you should or shouldn’t use because there are different schools of thought here. However you do want to ensure that you have successfully protected your surfaces from wandering streams of water and whatever other negative effects soil and ground moisture can have on your container.

Shipping Containers and Toxins

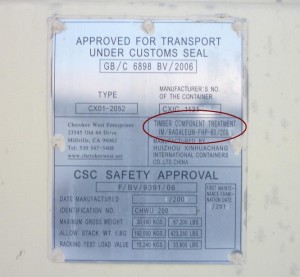

The very last things to consider are the potential toxins that come with the territory. Both the floor and the paint could potentially hold toxic chemicals, whether they were used to treat the surfaces at the point of origin or to fumigate the cargo in transit, pesticides are definitely something to consider when you intend to live or store things in a cargo container. Australia has some pretty strict pest control regulations and let’s face it…There are millions of shipping containers out there and who has the time to track which ones have been where, so everybody fumigates to Australian standards. This leaves pesticides trapped in the wood of the floors and leaves the possibility of potentially harmful vapors being released over time. There are a few ways to deal with the paint and floors when it comes to this. Rip it out! You could tear out the entire floor (or in case of the paint, sand it) and replace it with something a little more safe and aesthetically pleasing. Or you can seal it in with an epoxy or some other carefully chosen paint/sealant that doesn’t have harmful characteristics. The original toxins can be identified using the placard on the outside of container.

This carries the codes of most of the specs of the container including which pesticides were used to treat the floors and the type of paint used on the other surfaces. Consult this and then decide how to proceed from there. There are numerous forums and articles based on this subject and a simple internet search will result in quite of bit of information about the subject.

Safety

The very reason for this post… Above all, be safe when working or playing. You are presumably building something like this for protection or safety, so take the time to make sure that it does you no harm! Choose your container carefully, ask for help when you need it and if necessary consult a qualified professional engineer (or architect) throughout the phases of your construction. Remember to reinforce your structure where needed, and remove/encapsulate any potentially hazardous residue from the units previous life. Also… Don’t forget to buy your containers from Cherokee West Enterprises.

Cherokee West is your outlet for new and used shipping containers, connex boxes and metal storage containers. Our containers are guaranteed to be the highest quality on the market, with customer service to match. Built to stringent industry specifications, our cargo and shipping containers are theft and weather resistant, and can be modified to meet your individual needs.

19 comments

Skip to comment form

Author

JD

Thanks for the very informative article. Looks like there is quite a bit more to it than sticking a box in the ground and calling it a bunker!

PJ

You’re welcome.

Thank you for the opportunity to contribute. I definitely enjoyed writing this.

Fantastic info!! boxes are the first choice of all the packaging supplies when it comes to transportation of lot of items and product safety from one destination to another. Keep sharing such more.

The water level is definitely an issue in s. Louisiana, had given thought to that as well. What about earth covered mounds, they are used in Arkansas.

Being rather dense and new to this, What is the overall costs of a container, on average?

It will depend on your area but I picked up two (40 footers) for $3,000 each delivered. These were “one ship” containers in good shape, with good seals, and good paint.

How about you simply ask someone that has already done it with good results?

I did it 7 years ago. Dry, stable, no bowing, 3 feet down. This is how i did it. Dig a big hole, posthole dig the corners 4feet deep 24 inches across. Pour concrete in holes to level. Place container (tricky part) corners on footings you just made. Build 4 to 5 inch forms 18 inches high starting at the base. Reinforce with rebar. Pour concrete and let harden. Repeat until you reach the top of the container. Be sure rebar passes through all concrete from top to bottom without interruption. Basically use lengths that are about six inches taller than the box. Tie vertical rebar to horizontal sections with proper wire. Support roof with 2×4 from inside every 36 inches in a grid pattern from side to side front to back. Reinforce roof with more rebar. There are lots of web sites that show how to do this properly. In one pour lay the roof in 10 inches of concrete as a cap connecting to your walls and encapsulating the remaining wall rebar sticking up. Build with cinder block and concrete with rebar a staircase and entry on one end. I did this before roof pour so i could cover it with the same slab across entire roof. Cover entire structure with concrete seal and heavy plastic sheeting to direct moisture away. Cover with dirt. Remove interior supports after 30days for maximum cure strength. Safe, effective, strong, durable, and most of all fairly cheap. I have parked a 2000 pound tractor on top of it for months at a time. No problem. If you want extra insurance put a concrete support piller in the center of the interior. Dont one person say it dont work i personally know it does. Built in the same manner as things like overpasses. Be smart. Be safe. Think ahead. I put a small homemade septic tank and plumbing in as well. Also built a add on on one side with a small access door for my generator. With a tube up for intake and a series of mufflers in concrete sewer pipe up for exhaust. Buried a 500 gal fuel tank with a fuel line to generator about 50 feet away. Anyway thats how its done proper. Its a good idea to fill the sides with sand up against your walls. Moisture passes faster and dont hang around. Pick a elevated spot to avoid flooding through the entry and enjoy.

Also place drains in entry floor and inside box. Just in case. Total cost.

Container=free it was a gift

Rebar 800

Concrete 2400

Entry way/staircase blocks 200

Biggest costs were things i added like toilet, plumbing, wiring, generator, intake and exhaust vents with 12v fans, ect…

Cost is determined by a few main factors. First of all, availability is a big deal, sometimes one size or configuration is harder to get in a certain area than others so it may cost a little more. Condition is always a major factor.. New/Used/Refurbished definitely affect the base price of the unit. Delivery is where things really start to add up though, it definitely depends how close/far you are from where the unit is being sourced.

Most companies will provide a free quote, and will do the legwork involved in figuring out what it takes and how much it costs to get a container to you. Feel free to hit the link above and request a quote if you’re interested.

Author

Thanks for the clarification JD. I would imagine delivery would be a substantial portion of the cost when purchasing a shipping container.

Will rhino paint on container its just for outside… will it effective??

calling it a bunker is unsuitable now, I thought this article maybe lead a direction for buying shipping container, but a container shelter

Thank you for your article, very informative. Curious what your opinion is on the way some might weld two containers together. Is this possibly a structural hindrance to the integrity? Also I’ve read other articles in which one said they used a “truck bed liner” type coating to water seal a container. Have you ever come across this in your industry and what opinion might you have on this topic? Thanks for your time. BCravens

this is an almost useless article. a mere pontification.

an old man waffling on.

if you want to bury a shipping container you must reinforce it and do it well.

it will take about $6-700 of 70x50mm c section steel, welded. and you need to consult an engineer. peroid. full stop.

Author

So…you work in the industry (as does the author of this article)? I’d be curious to see the article you have published and read about all of the containers you have sold / buried for clients. 🙂

Great article with lots of informations. Thank’s for sharing.

I do have a quastion. Is it possible to use a shipping container as a bridge for crossing a small stream in the woods? I do intend to submerget it in a water and drive over it. I would reinforced the walls with lumber and open side doors for water to run through. What would be a life spam for that container?

Thank you your answers.

I would expect it will not last more than a decade or so… it is thin steel and will rust quickly with running water going through it. Esp if you need strength to drive over it, I wouldn’t expect it to last more than just a few years at that strength. Go for something concrete.

Bad idea. Wont last five years. Just build a real bridge. Concrete footers on each side for ten inch i beams that cross use heavy rail tie type wood across i beam and done. Your plan is frankly a waste of a container box.

I’ve given consideration to combining the Earthship idea of rubber tires, reinforced with Adobe or concrete to form a structure to surround the container before lowering it down. Afterwards, framing a roof support strong enough to resist the weight of the soil on top. If formed as a base, as well, it could provide an additional barrier against moist earth or flooding.