There is great satisfaction to be had when pulling the trigger and sending forth a projectile from the barrel of a gun, especially when one goes through the trouble to produce that cartridge. Assembling the projectile, casing, powder and primer…not to mention all of the prep and research involved before ever stepping foot on the range. In the prepper community reloading can also be looked upon as another form of self reliance, as long as one has the proper components there is no need to rely on commercial distributors for ammunition nor does one fall victim to price gouging or irrational laws related to quantity restrictions.

Before I go forward I’ll just state that I do NOT consider myself an expert in the reloading realm, however 3 years of experience has taught me quite a bit and because of that I’d like to share some of that with you. What this really is about is the difference between reloading for plinking and reloading for precision. Pumping out 100, 500, 1000 rounds of 223 for various drills at the range or 50 rounds of 308 for a bolt action rifle at distances of 100 / 300 / 500 or more yards. Again I still consider myself in the “learning phase” so if any old timers want to contribute please feel free to.

First let’s take a look at loading for production, or plinking as many refer to it. Obviously I’ll research my loads and test them, but once I have a good combo I’ll set out in this manner, with my Lee Turret Press.

Production:

– 100 – 200 rounds at a time (anything more gets tedious).

– Once the cases are prepped I go into full production mode.

– Did I mention prep? That involves a power drill and a bucket.

– Now I’m ready for the press: de-cap (de-prime), re-prime, dump powder, seat bullet (projectile), crimp.

– I utilize the powder dump feature on the Lee Turret Press, which allows me to go much faster.

– I test every 10th round or so, dumping the powder from the case onto a scale to check grains and once assembled measuring overall length (OAL). I call it quality control, assuming that if every 10th round is decent the in between rounds should be good to go.

– I can usually crank out around 100-200 rounds in two hours, after which I call it good and wait to pick up the effort another day.

– To date I’ve had no issues with my reloads, most of which have been very accurate at nominal distances. No FTF / FTE etc.

Precision:

Totally different ballgame here. This is where tenths of an inch count with respect to POA and POI. This is the nut I’m still trying to crack but am working hard at it. Meticulous might begin to describe how I address reloading when it comes to precious rounds for my bolt action rifle. If I can pump out 100 rounds of 223 in an hour, I might be able to assemble 10-15 precision 308 rounds.

– Case prep isn’t an assembly line process. I do one case at a time, by hand.

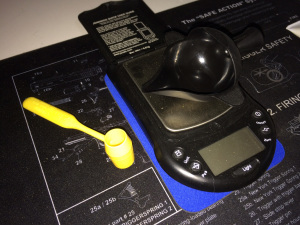

– I also make sure to calibrate my scale several times throughout the process.

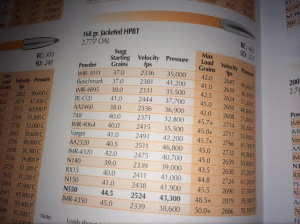

I also reference my reloading manual quite a few times during the process, making sure I have the right measurements for the components that I am utilizing.

It’s not to say that I don’t run into issues, like a fully lubed case getting stuck on the de-capping pin and needing to be cut off!

Whereas I dump powder with the Lee equipment and measure every 10th round while in production mode, I dump powder by hand and measure every grain when loading for precision.

The end result is something to behold! 168 Grain SMK 308 with IMR 4895 ready to rock! 2.775 OAL, just like the book recommends.

For more information related to reloading and how to get started, check out these two posts:

Reloading Ammunition, How To Get Started

Mobile Ammunition Production, The Lee Hand Press

7 comments

Skip to comment form

I’ve been reloading pistol for a couple years now. Started with 45 and then 40. Rifle rounds are a whole new world. I don’t know if I’ll ever get there, not until retirement at least.

Pistol was surprisingly easy and I have had excellent results.

Echo, reloading riffle is just as easy as the handgun stuff, the case prep is a little more sensitive, trimming the case length, case inspection, and all, but if you have a good press, it’s a piece of cake. I use the same press on my smaller stuff (204-223-243) as I do for pistol loads.

To be honest I have said “wait till retirement” myself a lot. But the heck with it, I make it a policy anymore to just jump in with both feet and see how deep the water gets… LOL

Good article PJ.

I’m also an avid shooter, Like you I do not consider myself an expert by any means, been reloading for many years now. I do a few competitions just for the fun of it (I don’t go crazy like some do). If ever you get a chance shoot a 22 long range comp sometime, it’s a blast hitting a 4” dia target at 200 meters with an all lead 22.

I totally agree with you in the production side of this, I use a Blue Dillon 650 with auto shell feed and can pump out 700-800 45-ACP an hour if needed. Sure burns a lot of supplies fast though. But hitting the range at about 1/5 the cost of new and when you dump 1500 rounds in 2 days, wellllll you get the picture.

As far as precision, I load my own black power 45-70’s by hand and some 30-30 and 50cal. Other than that I relay on good old HIGH DOLLAR store bought precision stuff for the 308 and bigger stuff.

Testing to make sure the loads are correct is a MUST!!!!! I check every 5th round on the big stuff and every 20th to 30th on the Blue Dillon (FYI it’s very accurate).

A little story, a buddy of mind was just getting into reloading; he inadvertently doubled the power load, and ran one through his nice $2800 dollar 45. He got lucky it only blew the side out of the barrel. Again check and recheck your loading procedures and loads.

Speaking of supplies, for brass you might check your local CC instruction guys. 90% of the people taking the class or test will not pick up brass, I have picked up used brass for $60 per 1200 for 45-ACP and $35 for 9mm. Be sure to inspect and recheck the brass, but you will find 99% is new/once fired. Also order power online, it takes a while to get it sometimes, but a lot cheaper that at the local gun shop, the same with precast bullets and primers. And if the urge really strikes ya, get into casting your own lead bullets; just don’t smell the “roses” so to speak with the lead.

There is a LOT of info out there, but if you dump 1000-2000 rounds a month, you really need to reload. Now if I can just figure out how to reload those stinking 22’s… HAHAHA And what the hell happened, I use to buy 22’s for 10 bucks a brick, now they are $80-$100 for stinking 22’s!!!!!!! Sheeeeesh.

Thanks again PJ, keep up the good work of making us all think a little more.

I have a hand press and not much time to deal with the extra case work. Pistol only for me for awhile. Plus, I don’t shoot much rifle ammo. Not enough to invest my time.

I have been saving the old lead boots from the vent pipes to cast my own bullets someday as well.

For pistol it’s easy, cheap and I think better ammo. I havent had any problems with them.

It is interesting that this subject should come-up at this time. I have been reloading since 1969 and most of my friends have also so I was more than surprised when a close friend called me the other day in a panic. His favorite 98 Mauser suddenly wouldn’t keep his shots on paper at 100; 75 or even 50 yards.

To make a long story short we checked and rechecked everything. Sights, rifle bedding, trigger pull, barrel rifling, the barrel throat, bolt lock-up and when those were OK we started looking at his ammunition. We turned the case necks, then reamed the necks, checked power charges to the point of zero variance. We weighted bullets, and brass so that there was no difference in cases or bullets then loaded a new batch of ammo. To say the results were disappointing would be an understatement. We had fliers going all over the place. It was truly amazing, and at time humorous how inaccurate the bullets were, we even had some bullets key holing at 50 yards. Thankfully we were on his own private range because it would have been embarrassing at a public range.

In desperation we finally decided to buy a box of factory ammo and see if there was something we had missed. Firing the factory ammunition was something to behold. That Mauser 98 laid 3 groups of 5 shot each in a MOA at 100 yards like it had always been capable of.

As we sat and stared at each other it suddenly dawn on me that he had changed bullets from 175 or 160 grain to a 120 grain bullet. When I mention the change his immediate response was “bullet length!”

That was exactly what the problem was. The Greenhill formula, which can be read about on Wikipedia, gives one the optimum bullet length for any twist rate. The formula is as follows: BL= (C/(T/BD))*BD.

Where:

BL = bullet length in inches;

C = a variable 150 is used for muzzle velocities less than 2800 fps and 180 is used for muzzle velocities greater then 2800 fps;

T = the rifles twist rate 1 in X inches;

BD = the bullet diameter in inches.

The correct bullet for your twist rate can make huge difference in how your rifle performs.

Author

Wow! Great story! Thanks for sharing the information about proper bullet length, it takes it a step further than what the manual prescribes. I found more information here

http://www.lasc.us/ConversionTables.htm#Greenhill

Interesting story Muleskinner

Things sure have changed since the old days of dumping a little Black into the end of the stick, stuffing a small chunk of rag and a hunk of lead in the end and pounding it down with a rod, adjusting the flint a little and pulling the trigger… LOL And of course waiting for the cloud to clear…….. I DO LOVE Black Power 🙂

Point is, any time you change anything in your loads, even a different manufacture of the Primers, it can affect your down-range accuracy.